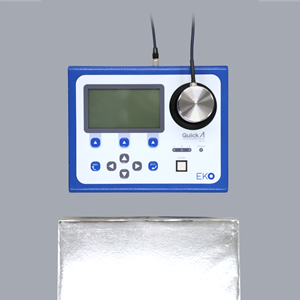

HC-121 VIP Checker

- Quick response VIP tester

Overview

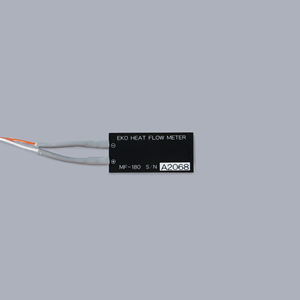

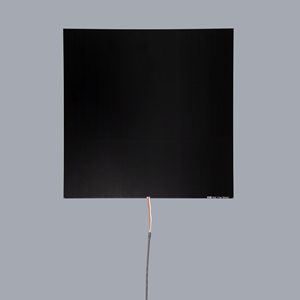

HC-121 is used to check the performance (Good / non-good) of vacuum insulator panels (VIP). It measures thermal conductivity by means of heat loss. This measurement method takes a very short time compared to traditional methods and has a big advantage since the materials can be evaluated only from the top side. The HC-121 has a combined heat source and detector called sensing head which proportionally measures the heat loss through the detector and insulating material. In most common solutions a test sequence that takes more than 1 hour to measure the thermal conductivity of 1 sample, the HC-121 need only 1 minute which will shorten the production time of VIP drastically.

Vacuum Insulation Panel (VIP) Checker HC-121 is developed to check the quality, estimated thermal conductivity, of VIPs at the final production stage. When VIPs have insufficient sealing of laminated film or changing of material characteristics inside, the thermal conductivity of VIPs will increase. HC-121 can check the condition of increasing thermal conductivity as OK or NG index. A maximum of 5 sensor heads can be connected to the main unit and can be handled independently.

As the HC-121 can only perform a relative measurement the measurement heads need to be individually calibrated at the customer side using characterized material samples that are equivalent to the VIP material tested for production purposes. The EKO calibration software is used to find the calibration regression function defined by the coefficient a,b and c. The control software is used to control the thermal conductivity tester and manage the measurement data. It can be connected to a bar code reader in order to identify and register all VIP samples.

Specifications

| Attribute | HC-121 | ||

|---|---|---|---|

| TC Measurement range | 0.001 - 0.015 W/m•K | ||

| Measurement accuracy | +/- 5 % | ||

| Test Material Size | 150 - 760 mm | ||

| Test Material Thickness | 5 - 50 mm | ||

| Input channels max, 1 probe standard | 5 | ||

| Measurement time | 60 s | ||

| Operating temperature range | 0 - 40 °C | ||

| Measurement unit communication | RS-232 / USB optional | ||

| Dimensions mm | 320 (L) x 120 (W) x 220 (H) | ||

| Weight | 3 kg | ||

| Power supply (Power Adapter) | 100-240VAC, 50/60Hz | ||

| Options | |||

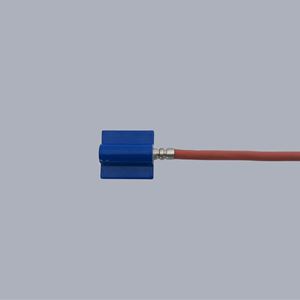

| Probe | 54 (D) x 117 (H) / 1 kg | ||

| Display unit | 200 (L) x 130 (W) x 120 (H) / 1 kg | ||

How it works

How it works